If the energy and cost of living crisis this winter teaches us anything it’s that as homeowners we should have as many heating options at our disposal as possible. We have had an air source heat pump for four years, and we’ve learnt a lot of practical lessons during this time.

As a rural property, we have off the grid neighbours and it’s very interesting to draw parallels between the way they heat their houses and the way we heat ours. For starters, we have about 25 “neighbours” and we are the only property with an air source heat pump. Some of the houses are heated by LPG, but most still use oil boilers. And if you were take a survey of rural properties in the UK (approx. 1.7 million houses) you’d find that most are still heated by kerosene.

The thing is, a well designed and installed heat pump can effectively heat most rural properties in the UK. As we’ve covered across countless blogs and videos on the subject, our heat pump was reasonably well installed, but it needed a lot of tweaks and upgrades to get it working more efficiently and to heat the house.

It’s still far from perfect but from March to mid-November our heat pump solely heats our property and hot water, where it’s aided by our solar PV to offset running costs. This makes our heating and hot water production eco-friendly for large chunks of the year.

That leaves us with the winter months to deal with, and I think that rural homes that have heat pumps fitted should retain their oil boilers and run their systems bi-valently (or as hybrids, if you prefer that term) using biofuels. There’ll be a lot of people that will disagree with this suggestion, but here’s my rationale.

Homeowners, like I said earlier, need options to run their heating efficiently. The way that we have configured our heating to work is for the heat pump to heat the house (and hot water) when temperatures outside exceed 7C. At those ambient temperatures, our heat pump is still reasonably efficient at heating the house and maintaining a flow temperature of 45C to keep our inside target temperature of 21C in our main living areas.

In late November temperatures start to drop, so we’ve set up our system to kick over to the oil boiler (that runs off a biofuel called HVO) when temperatures drop to 7C and below.

The reason for this is that our air source heat pump starts to become inefficient at these temperatures and when you get to 0C and below, the heat pump is costing a lot of money to maintain and run.

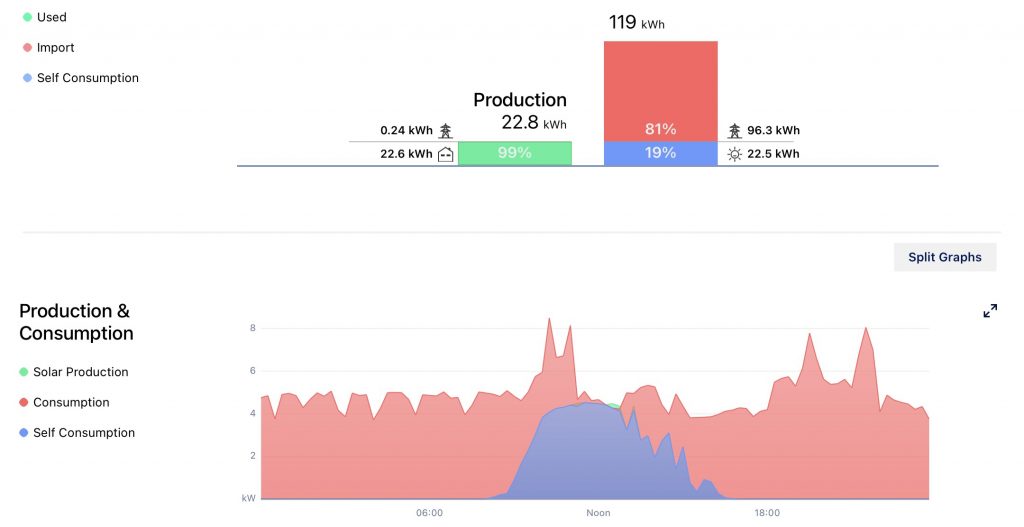

As an example, we dropped to -3C in early December and we used our heat pump for 24 hours to heat the house to see how expensive it would be to run.

During this time we consumed 119kWh of electricity, of which around 100kWh would have gone to heating the house. A crazy amount of energy. At our current tariff, that was a staggering £36 for 24 hours of heating. Not only was this terribly expensive, the 45C flow temperature managed to keep the underfloor heating areas comfortable, but some of the northerly bedrooms (and our TV room) really struggled to get above 19C.

That’s also a lot of electricity consumption at a time when the UK grid is taking major strain.

With the experiment over, we switched back to our go-to mode of heating, running things bi-valently. Because the temperatures were so low, still around -3C, our heat pump relinquished all heating duties over to the boiler, which as I mentioned is running HVO (with 88% less carbon emissions than kerosene).

To compensate for the reduction in outdoor temperature, and the associated heat losses, we increased our flow temperature by 5C to 50C. The main living areas were cosy and the northerly rooms that we mentioned struggled at 45C flow temperature on the air source heat pump, managed to get to 21C. Running the heat pump at a flow temperature of 50C with outdoor temperatures at -3C would have consumed more than 100kWh.

From an HVO running cost perspective, it’s prohibitively expensive to compare it to kerosene, electricity or any other fuel. More on that in a moment. If we were to heat our house using kerosene, based on this week’s oil club price of around 80p/litre, heating our property using kerosene would have cost us about £25 for 24 hours of heating. While cheaper, it’s not so much about running costs because all fuels are very expensive at the moment and given the volatility of the pricing, it could go up and the running costs would be equivalent.

From a comfort perspective, the HVO boiler is able to deliver more heat when you need it and it doesn’t really care if its cold outside because it doesn’t have the same efficiency concerns as a heat pump.

Having that fallback position is important because if we get a week or more of really awful weather with temperatures below -5C we don’t have to worry about heat pump inefficiencies and endless defrost cycles because we have an alternative that can keep the house warm, and increasing the flow temperature from 50C to 55C to compensate for lower outside temperatures is something we can do without significant running cost implications. Our heat pump doesn’t provide us with that level of flexibility.

One of the other benefits of running HVO is that when it is brutally cold outside, if you’ve got a solar PV system like we do, it can help power the house while the HVO boiler runs. For us, on cold, sunny days, we use excess solar to heat our hot water, which works a treat, and that makes us even more eco-friendly.

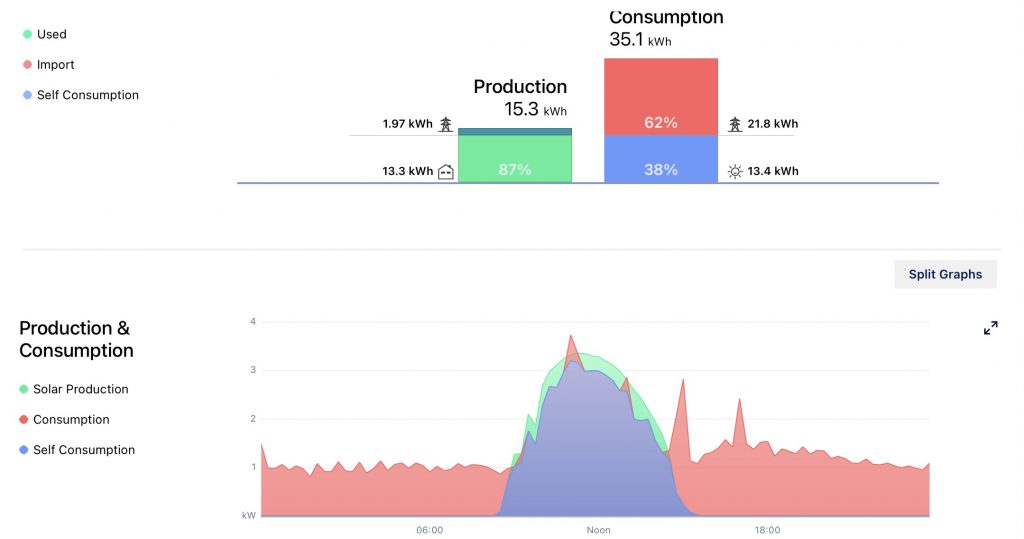

Here’s a great example of us running on HVO on a cold, sunny day. Because the heat pump is dormant we were able to utilise solar to turn the washing machine and dishwasher on in the late morning.

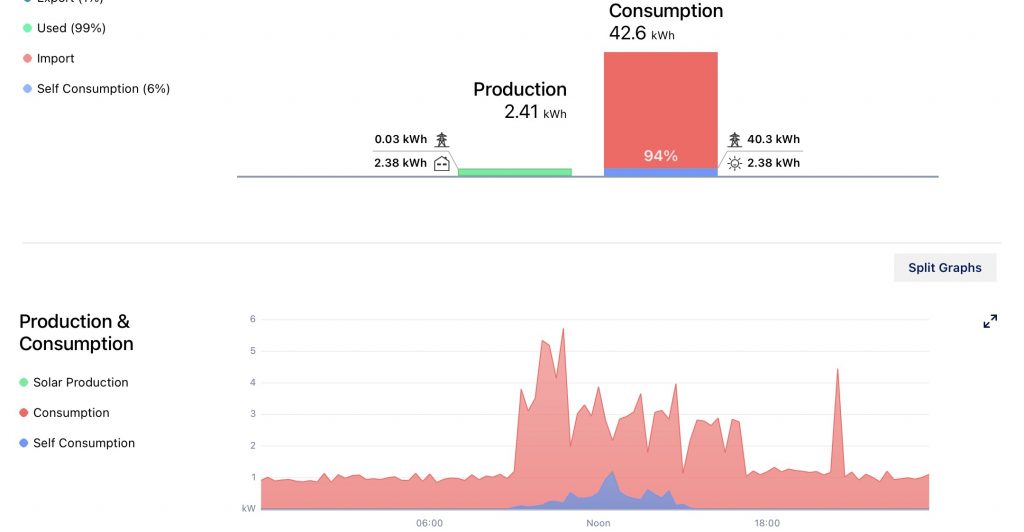

Next up, you can see the bi-valent system in operation. When it’s cold outside, our electricity use is constant. The reason, in case you’re wondering, why we average 1kWh is because of the insane amount of distribution pumps that were installed with our system because of poor design. We are planning to get this remedied this spring, and get our average usage down to 300-400W per hour.

But I digress. You can see in the graph below where the heat pump kicks in (when the temperature gets over 7C). Even at 7C, electricity consumption is quite heavy.

Why HVO is prohibitively expensive for heating in the UK and what you can do about it as a homeowner

HVO is currently eligible for a tax rebate under the Renewable Transport Fuel Obligation (RTFO) program in the transportation sector, which aims to encourage the use of low-carbon fuels in the UK, but these same rebates are bizarrely not available for home heating. So HVO is very expensive compared to kerosene because of these levies and taxes imposed on it as a heating fuel.

If your property is currently heated by kerosene in the UK, and you’d like to potentially switch to HVO to cut your heating CO2 emissions and reduce your carbon footprint, we encourage you to write to your member of parliament (MP), asking them to help scrap the duties and levies for home heating. To save you some time, we have provided a template that you can use and adapt. Download it here.

If you’d like more information on HVO, please visit this article we posted on our sister site, Renewable Heating Hub.

Differences between HVO kerosene

There are some key differences between HVO and kerosene.

One of the main differences between kerosene and HVO is the environmental impact. Kerosene is a fossil fuel and its combustion releases carbon dioxide (CO2), which is a greenhouse gas that contributes to climate change. HVO, on the other hand, is a renewable fuel made from vegetable oils or animal fats. It has a lower carbon footprint than kerosene because the carbon dioxide released during its combustion is offset by the carbon dioxide absorbed by the plants used to make the fuel.

Another difference between kerosene and HVO is the efficiency of the fuel. HVO has a slightly higher energy content than kerosene, which means that it can provide more heat per unit of fuel. This can translate into cost savings for homeowners who use HVO as a heating fuel.