I’ve wanted to home-brew beer for years, and things have finally lined up for me to do so. To build up my confidence, I did a small nettle beer home brew earlier this year which was a good test run for our Czech style lager. I didn’t want to invest in loads of equipment to home-brew, so I’ve adapted to using what we had in the kitchen cupboards, and only purchased a small amount of add-ons (amounting to less than £25).

We purchased two 5-litre glass demijohns (with bung and airlock), a mashing bag and hydrometer. The ingredients are obviously extra, and this is what we purchased and used for our first ever batch of lager:

Lager malt (crushed), Mangrove Jack’s Bohemian lager yeast (M84), water purified using filtration jug, and brewing sugar. Quantities and amounts are mentioned as part of the step by step guide below.

Czech style lager – step by step brew in a bag process

The process we used is called ‘brew in a bag’ (BIAB), which is why we purchased a mashing bag, and I can vouch that it’s an extremely easy way to make beer. You just have to be precise in following the recipe and adhering to timing.

To start, bring 6 litres of water up to 75C (strike temperature) in a large stock pot (ours is 11 litres). We purchased a mashing and sparring bag to fit our pot. We placed it inside the pot (pulling the draw string closed) and allowed the water to get to temperature. Keep the lid on to prevent evaporation.

We also placed a small colander right at the bottom of the pot so that when the bag is filled with malt grain it won’t touch the bottom of the pot and will reduce any chance of burning, which can potentially ruin or alter the taste of the lager.

Once the water is ready to go, place 1kg of pilsner malt inside the bag in batches, stirring as you go along to ensure that it’s not clumping and that you’re getting an even coverage of water.

Now it’s time to mash in, by maintaining a mash temperature of 65C for 60 minutes. In our case, when we placed the malt into the pot, our temperature dropped to 66C. We put the lid on and turned off the oven. Because the hot plate remained hot, we were able to maintain a temperature of 65C by not doing anything. As this cooks, you’ll notice that a gentle, sweet smell starts to fill the room.

Once the 60 minutes is up, it’s time to mash out by raising the grain temperature to 75C and we maintained it here for 20 minutes. We used a cooking thermometer to monitor the temperature, and took temperatures from the centre of the grain, as you would with a roast.

With the mash out completed, we removed the bag from the pot (it’s not very heavy, but it is hot, so be careful) and we got a larger colander that we placed on the stock pot and pressed the bag to release as much as of the liquid (wort) back into the stock pot.

You can dispose of the malt now – in keeping with our sustainability ethos, our grains went straight onto our compost heap. Bring your water to the boil – before it does, take a small teaspoon and taste the wort. It’s deliciously sweet.

It’s now time to heat up the wort. When it’s back at a rolling boil, add your first wort hops – 20g of Saaz for our Czech pilsner – and boil for 60 minutes. 15 minutes before the end of the boil, add your bittering hops, another 10g of Saaz. I like to savour and taste things, and after just 20 minutes of boiling, I took another taste and it’s amazing how bitter our sweet wort has become.

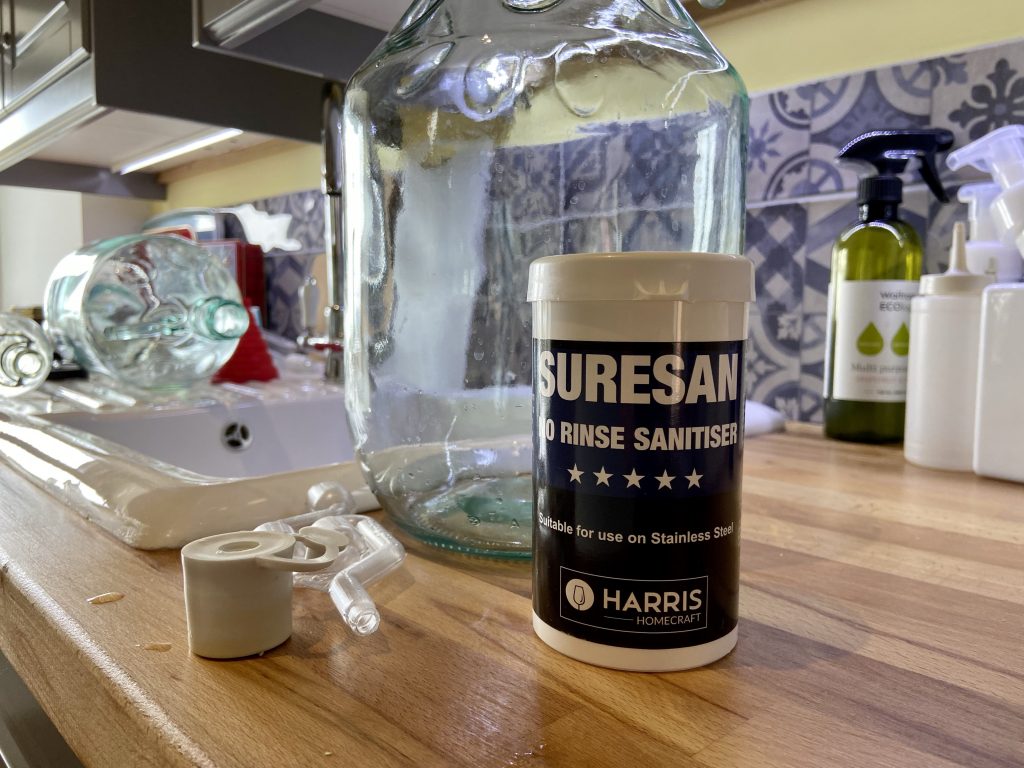

During this process we sterilised our demijohn, bung and airlock. We used a no rinse sanitiser from Suresan, and it worked incredibly well. Highly recommended.

The next step, in a home kitchen, is the most challenging part of this brew. Chill the wort as close to 10C as you can get it. To overcome this, we used out kitchen sink. We placed the stock pot in the sink and filled it with cold water. Every time the water got warm, we emptied the sink and refilled it. If you have a fridge, you can use that too, but the cold water trick worked really well.

When it’s nice and cool take a gravity reading using your hydrometer.

Now transfer the wort to the demijohn (which has been fully sanitised). In order to aerate it, we used a small filling jug, and allowed the liquid to cascade into the demijohn.

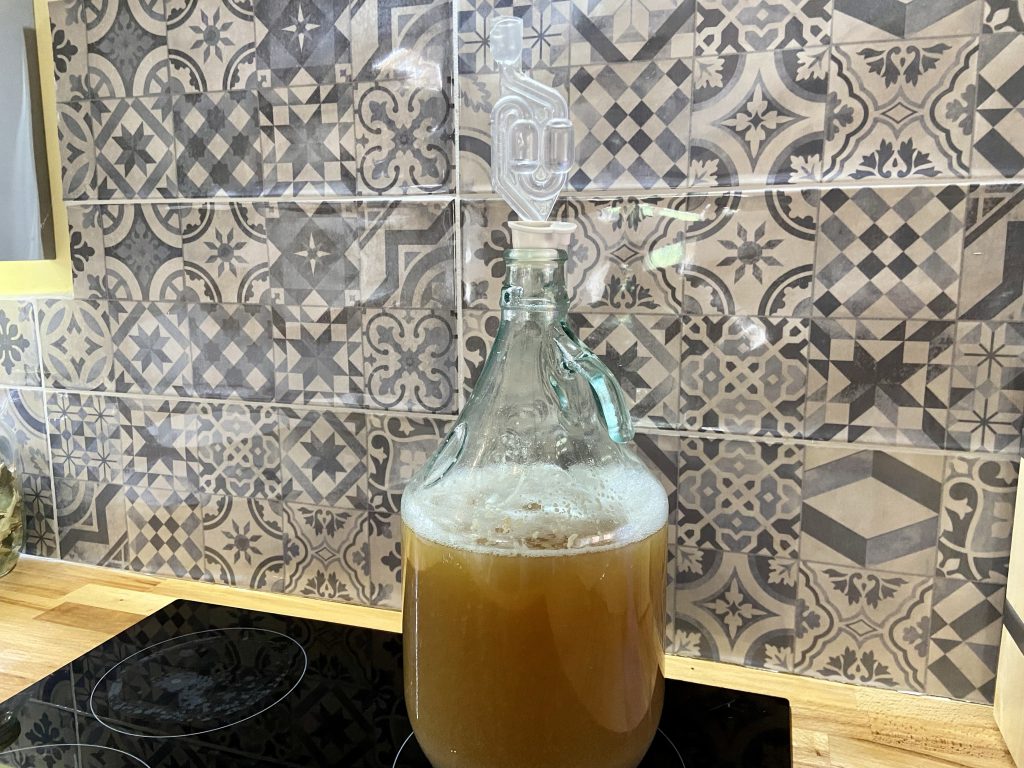

Next, pitch (add) the yeast, and maintain the demijohn at between 10-15C. We used half a packet (5g) of Mangrove Jack’s Bohemian lager yeast (M84). The closer you can keep it to 10C, the better, and the way we tried to accomplish this was by using our sink bath again.

The bung and airlock go on next, fill the airlock with water, and let the brew ferment.

Ferment in the demijohn at between 10-13C if possible. We have a drinks fridge so I placed the demijohn in there (because it is quite small). We came up with a cool hack to maintain our temperature by using an Eve Room and Eve Energy, which you can check out here.

We left our beer in the fridge for 16 days, until activity in the airlock all but stopped. We dissolved 30g of brewing sugar in a small amount of hot water, and allowed it to cool down.

We removed our demijohn from the fridge and took another gravity reading. We then added the cooled down sugar to the wort and proceed to bottling the beer in flip-top bottles. This sugar, in case you’re wondering, assists in the carbonation process, and it worked extremely well. Check out the video to hear the pop.

This is where lagers can get even more complicated because you should ramp the lager temperature up by 2C every 12 hours. We didn’t bother with any of that.

We simply maintained our beer at 10-13C using our Eve Room and Eve Energy, hack, and allowed the beers to condition in the flip-top bottles for 14 days. We also didn’t add leaf gelatine or any other clarifiers. I like unfiltered beers, so our beers wasn’t golden in colour, but that doesn’t bother me.